Jesus Nut Nightmare - 1969

.....................................................................................................................................................................................

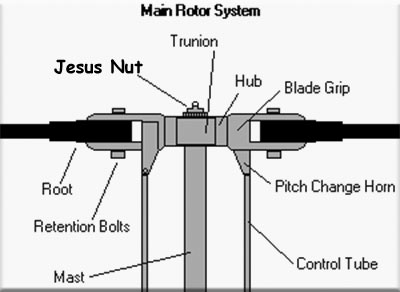

The Jesus Nut. On the helicopter mast coming out of the transmission, mechanical components such as the Swash Plate, Collective sleeve/plate, and Mast head are all held in place by machined fits, and to keep everything in place is a cone/cap like nut fits on top, which we called the Jesus Nut.

The Jesus Nut. On the helicopter mast coming out of the transmission, mechanical components such as the Swash Plate, Collective sleeve/plate, and Mast head are all held in place by machined fits, and to keep everything in place is a cone/cap like nut fits on top, which we called the Jesus Nut.

This Nut is torqued down to several hundred foot pounds. When torqued, it is also safety wired and slippage marks are put on it and the adjoining stationary pylon. It is one item that is looked at on daily inspections by crew chiefs and pilots, to make sure that nothing had slipped or changed. However, in reality that inspection probably wasn’t necessary, because if it had loosened or changed, more than likely a mechanical failure resulting in a crash would have already happened. As the saying goes, if the Jesus Nut failed, “you ain’t gonna fly much longer anyways and your life was in the hands of Jesus.” see also Jesus Nut by Bob Graham

We had torque wrenches on a smaller scale, and in order to achieve the demanded torque, it was necessary to borrow a 3-1 torque multiplier from 725th Maint. We would adapt our smaller torque wrench to the multiplier, set our torque wrench to one third the required setting, and achieve the required torque. (That multiplier tool could be used on that nut for removal or for torqueing.) At that time, I had several new men that had come into my maintenance platoon and this may have been one of the first time for them to remove the components on the pylon. As a supervisor/mechanic, I gave two of them the task of going over and borrowing the torque multiplier from 725th Maintenance, and not only did they get the torque multiplier, but also a torque wrench large enough that could be set to the proper torque without using the torque multiplier. The TM gave the specified torque, and they could set this Larger Torque wrench to that required amount, not needing to use the torque multiplier. However, this day with the Larger Torque wrench, they also used the multiplier along with the Larger Torque wrench set at the specified torque and the result was that the Jesus Nut was torqued to three times the amount required.

We had torque wrenches on a smaller scale, and in order to achieve the demanded torque, it was necessary to borrow a 3-1 torque multiplier from 725th Maint. We would adapt our smaller torque wrench to the multiplier, set our torque wrench to one third the required setting, and achieve the required torque. (That multiplier tool could be used on that nut for removal or for torqueing.) At that time, I had several new men that had come into my maintenance platoon and this may have been one of the first time for them to remove the components on the pylon. As a supervisor/mechanic, I gave two of them the task of going over and borrowing the torque multiplier from 725th Maintenance, and not only did they get the torque multiplier, but also a torque wrench large enough that could be set to the proper torque without using the torque multiplier. The TM gave the specified torque, and they could set this Larger Torque wrench to that required amount, not needing to use the torque multiplier. However, this day with the Larger Torque wrench, they also used the multiplier along with the Larger Torque wrench set at the specified torque and the result was that the Jesus Nut was torqued to three times the amount required.

Before the aircraft came out of the hanger, I would take the paper work and with each mechanic go over everything that was done to the aircraft. When I got to the part of the torqueing of the Jesus Nut, I asked the mechanics to explain to me what they had done. They told me how they had borrowed the torque multiplier, and the larger torque wrench, made the settings on the torque wrench, and torqued it. I think my heart fluttered. I asked them to repeat what they had done. They did, and I realized that a grave mistake had taken place.

I then told the problem to my superiors, and then attempts had to be made to correct the mistake. We would need to remove that Jesus Nut, inspect for thread cracks, etc., and replace as needed. But, it would not be all that simple. That “Jesus Nut” would not break loose. We broke tools trying to get it loose, and finally had to go get Engineers to come and weld a beam to the Jesus Nut. Finally several hours later after much breakage and frustration, we got the nut to come loose.

Upon examination, we found the threads to be galled on both the Jesus Nut and the pylon, with the pylon showing cracks and that meant we had to change the pylon out (the Mast). It meant pulling everything apart, and replacing the pylon itself. The task of changing out the pylon itself is a tricky maneuver. The portion of the pylon that goes into the transmission cannot be touched with bare hands, because skin oils may contaminate the surface and cause etching problems later on. Special gloves were worn. I will say this, not one commander/superior of mine, nor any pilot, chewed me/us out about the incident. And, I did not discipline any of my men for the mistake. Chances are, that Jesus Nut would have failed. It might have failed on the test flight I would have been on, or maybe lasted longer and fail with its combat crew. A lesson was learned, and finally we got a proper Larger Torque wrench and did away with the torque multiplier for torqueing the Jesus nut. KC